1

0

-

y

e

a

r

e

l

e

c

t

r

i

c

a

l

r

e

s

i

s

t

a

n

c

e

warranty

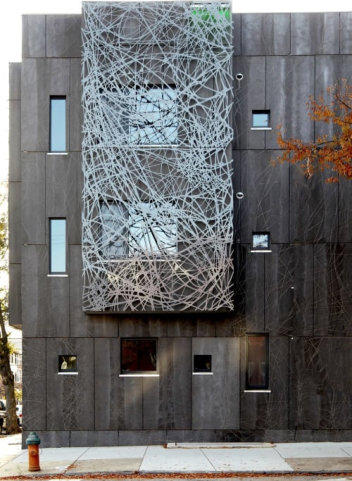

VIROC FIBER CEMENT

Thicknesses and dimensions for BLACK and GREY colours:

Thicknesses (mm): 8 | 10 | 12 | 16 | 19 | 22 | 25 | 28 | 32

Dimensions (mm): 2600 x 1250 | 3000 x 1250 and

others under consulting

Thicknesses and dimensions

for WHITE | SOIL | YELLOW | RED colours:

Thicknesses (mm): 12 | 16 *

Dimensions (mm): 2600 x 1250 or others under consulting

Viroc® Cement Bonded Particle Board is a composite material,

composed by a compressed and dry mixture of pine wood particles

and cement.It combines the flexibility and durability of wood with

the strength of cement, allowing a large range of applications, both

indoor and outdoor. Viroc fiber cement presents a non-

homogeneous appearance, a product natural feature. Once

calibrated, presents visible wood particles on the surface. A natural

feature of the Viroc fiber cement panels is the tone difference on its

surface. They are widely used as exterior cladding and do not

require maintenance. The most important feature of VIROC fiber

cement sheets is that they are colour – through. Not only the

surfaces of the panels but the cores are produced in colour.

Therefore, the panels are also called “dyed- trough” or “colour-

through” panels. Composite cement panels with exposed concrete

appearance each have a unique appearance. Viroc fiber cement

sheets can be used as a whole or can be applied by cutting to the

desired size. Relief patterns can be given on the panels with CNC

machine and also can be used for decorative purposes in interior

wall covering by digital printing.Viroc fiber cement panels are used

as digital print wall covering in Starbucks Coffee branches.

APPLICATIONS AREAS

Facade claddings / Interior wall claddings / Floor coverings /

Ceiling cladding / Suspended ceilings / Acoustic claddings /

Jambs and balconies / Garden walls / Siding cladding / Under-

eaves and eaves facade cladding / Interior decorative cladding

material / Decoration / interior design / Roof coverings / Sub

support element for roofing materials / Furniture / Garden furniture

/ Prefabricated buildings / Prefabricated pool walls / Door / Kitchen

countertops / Stair covering / Bathroom counter and cabinet / City

furniture / Exhibition stands / Artwork / Material for wet areas /

Sandwich panel partition wall elements / storey line in multi-storey

structures / Jambs on doors and windows on exterior walls /

Siding applications / Showcase designs / Billboards / Support

element under flooring materials / Inter-floor flooring material in

multi-storey prefabricated buildings / Sub-ceramic floor material in

wet areas / Concrete formwork material / Sandwich panel with

various insulation materials

© SARGRUP İNŞAAT VE ENERJİ LTD.ŞTİ. T: +90 212 418 45 35 M: +90 532 211 27 94 E:

info@sargrup.com.tr

Non

Toxic

:

Does

not

contain

dangerous

volatile

compounds

and

is

free

of

silica,

asbestos

and

formaldehyde.

Sound

Insulation

:

It

has

good

sound

insulation

properties

due

to

its

high

weight.

The

sound

insulation

index

varies

according

to

board

thickness.

Airborne

sound

resistance

is

31

or

37

dB

depending

on

whether

board

thickness

is

8mm

or

22mm,

respectively.

Fire

Retardant

:

It

prevents

the

spread

of

fire.

According

to

the

ignitability

test

conducted,

it

is

classified as B-s1, d0 in accordance with EN 13501.

Insect

Resistant

:

It

will

not

degrade

with

the

action

of

living

organisms

such

as

fungi,

termites,

or

any

kind of insects.

Thermal

Insulation

:

It

has

good

thermal

resistance

properties,

meaning

that

it

can

function

as

insulation

in both cold and hot temperatures.

Moisture

Resistant

:

Under

the

action

of

water

it

does

not

disaggregate.

It

is

a

material

that

is

impermeable

to

water

and

also

resistant

to

water

vapour.

Weight

Resistant

:

The

board

has

a

bending

strength

that

enables

it

to

be

used

as

a

resistant

structural

element.

Therefore,

it

is

used

in

flooring

and

as

roof

support.

The

characteristic

breaking

strength

on

bending

is

10.5

N/mm2

with

an

elasticity

modulus of 6000 N/mm2.

ADVANTAGES OF VIROC FIBERCEMENT BOARDS

Easy

Installation

:

It

can

be

cut,

drilled

and

sanded.

The

tools

and

fastening

systems

used

for

Viroc

boards are identical to those used with wood.

Viroc is manufactured as a non-homogeneous material, with a

standard ‘rough’ finish that may present some shades due to the

composition of cement porosity and salts. Usually these shades

run in lengthways and sometimes appear as ‘lines’, the directions

as a result of the production line up. A natural occurrence on the

panel’s surface that may be more pronounced in some

productions than others due to properties of the raw materials. In

most cases this natural look or manufactured condition is what

makes the material attractive in the first place. If required, the

‘lines’ or shades can be smoothed by “polishing” the panel

surface but it will never disappear 100%. To polish the panel

surface it’s recommended to use a polishing disk (“scotch brite”)

or sanding disk of 180gr minimum. This procedure will remove

the superficial cement salts and will homogenise the panel

surface, smoothing out the natural shades. Where required, a

process undertaken at the factory.